I fell sick this week and was having trouble focusing on my writing. Coming up with a quality blog post felt out of my reach. Serendipitously I received a guest blog post from Graham at Float Tanks Solutions in my inbox. Please take the time to read this very thorough post on soundproofing your float rooms.

Enter Graham

A Few Float Tank Mysteries

A woman got out of her float at Float On and told us that there was a loud clacking, like someone tapping on something occasionally. This was shortly after we opened. Now, we don't wear 'clacky' shoes, Ashkahn wasn't tapping percussively on anything in our shop (this time), and (as far as we knew) there wasn't anything in the tank itself that should be tapping. We were stumped for weeks. It wasn't until another customer described it as 'sounding like high heels' that we traced it to the hair salon next door, and the stylists walking on the tile they had put down. We figured out a way to fix it, which we'll talk about below.

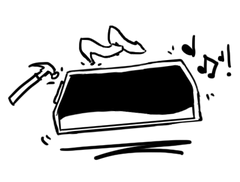

Then there was the rhythmic thudding, which we again found to be our neighbor, the shoe repairman (considering why we opened a sensory deprivation center next to a shoe repair shop should give you a good idea of our inexperience and unbridled optimism at this point). We thought it was one of his huge machines, but it ended up being one of his tiniest: it wasn't even loud in the shop, only in the tanks.

We fixed this as well.

Then there are the one offs, like the woman who got out because she thought she heard music when in fact it was just a sudden and very intense burst of hail against the ceiling vent. Or the time someone heard thudding which ended up being someone on our roof trying to burglarize our cannabis club neighbors (unsuccessfully). And at least three floaters a week describe sounds that only existed in their heads.

For everything we have fixed, there are twice as many mysteries that will probably never be solved.

We figured out a way to fix it, which we'll talk about below.

Then there was the rhythmic thudding, which we again found to be our neighbor, the shoe repairman (considering why we opened a sensory deprivation center next to a shoe repair shop should give you a good idea of our inexperience and unbridled optimism at this point). We thought it was one of his huge machines, but it ended up being one of his tiniest: it wasn't even loud in the shop, only in the tanks.

We fixed this as well.

Then there are the one offs, like the woman who got out because she thought she heard music when in fact it was just a sudden and very intense burst of hail against the ceiling vent. Or the time someone heard thudding which ended up being someone on our roof trying to burglarize our cannabis club neighbors (unsuccessfully). And at least three floaters a week describe sounds that only existed in their heads.

For everything we have fixed, there are twice as many mysteries that will probably never be solved.

Take everything you read here with a grain of salt, both for the obvious merits of float tank wordplay, and for the fact that a lot of this will probably change and progress along with the industry. If there's anything you've found works for you, definitely take a few moments to tell us about it in the comments - we're all in this together, and people will be able to immediately use your suggestions.

It is helpful to think of soundproofing for a float center as broken down into a few categories:

Take everything you read here with a grain of salt, both for the obvious merits of float tank wordplay, and for the fact that a lot of this will probably change and progress along with the industry. If there's anything you've found works for you, definitely take a few moments to tell us about it in the comments - we're all in this together, and people will be able to immediately use your suggestions.

It is helpful to think of soundproofing for a float center as broken down into a few categories:

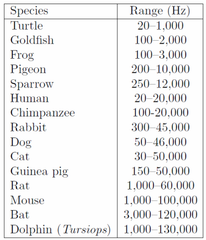

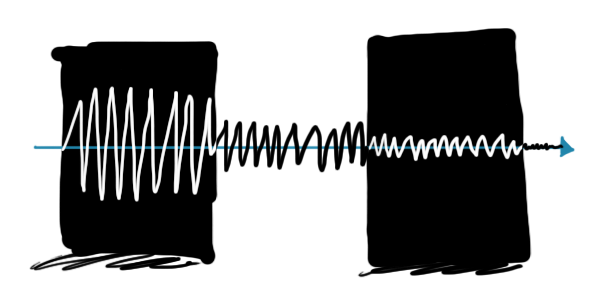

When we hear something, it's because the air particles around us are vibrating in a certain way. It's easy to forget, but sound is vibration, and our human bodies are only able to detect certain ranges of vibration (just as we can only see a very specific spectrum of light with our eyes).

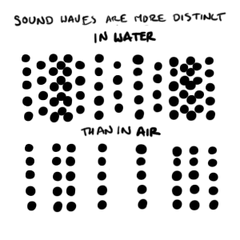

Because our ears are underwater, and vibration travels so distinctly through water, this is an especially important concept to grasp for float tank owners.

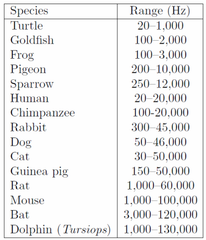

Unsurprisingly, a lot of animals can detect sound vibration (which, by the way, is measured in Hertz, after Heinrich Rudolf Hertz, who proved the existence of electromagnetic waves) which humans cannot. How do we know that dolphins can hear up to 130,000 Hz while humans can only hear up to 20,000 Hz? The same reason we have float tanks: John Lilly.

Of other interest is that different noises produce different ranges of sound, and different types of soundproofing guard against different ranges of sound. Want to block out human voices? How about the bass from your neighbors stereo? Soundproofing materials often come with charts and profiles of the kinds of noises they block.

Sound intensity is measured in decibals (dB) which progresses in intensity exponentially. You may know it mainly as an audio term, but it's actually used as a common scale for many things in physics.

Basically all of our soundproofing is to reduce the volume of sound (dB) within the human hearing range (20-20,000hZ).

When we hear something, it's because the air particles around us are vibrating in a certain way. It's easy to forget, but sound is vibration, and our human bodies are only able to detect certain ranges of vibration (just as we can only see a very specific spectrum of light with our eyes).

Because our ears are underwater, and vibration travels so distinctly through water, this is an especially important concept to grasp for float tank owners.

Unsurprisingly, a lot of animals can detect sound vibration (which, by the way, is measured in Hertz, after Heinrich Rudolf Hertz, who proved the existence of electromagnetic waves) which humans cannot. How do we know that dolphins can hear up to 130,000 Hz while humans can only hear up to 20,000 Hz? The same reason we have float tanks: John Lilly.

Of other interest is that different noises produce different ranges of sound, and different types of soundproofing guard against different ranges of sound. Want to block out human voices? How about the bass from your neighbors stereo? Soundproofing materials often come with charts and profiles of the kinds of noises they block.

Sound intensity is measured in decibals (dB) which progresses in intensity exponentially. You may know it mainly as an audio term, but it's actually used as a common scale for many things in physics.

Basically all of our soundproofing is to reduce the volume of sound (dB) within the human hearing range (20-20,000hZ).

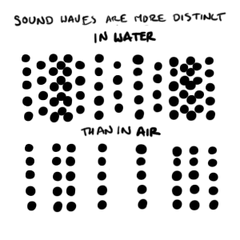

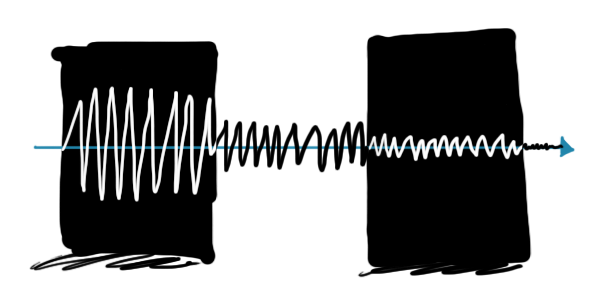

This transition from air to solid to air to solid is important, because soundwaves lose strength as they travel through different densities.The shift in density disrupts up the soundwave, which is why vibration isolation pads are made out of alternating levels of rubber, cork, and rubber. Dense, light, dense.

This helps us out a lot, since the transition from air to water loses a lot of sound as well. If our ears weren't such biological marvels that they had amplification devices built in specifically for water, we'd hear almost nothing as soon as our ears went below surface level. As it is, as long as people have their ears submerged (only really an issue if people are using neck pillows) that still does a lot of the heavy soundproofing for us.

And nothing is as large a transition as between air and solid.

So, one of the main goals of soundproofing becomes creating barriers with gaps of air between them. 'Heavy material and air gaps' is a good thing to imprint in your mind.

This transition from air to solid to air to solid is important, because soundwaves lose strength as they travel through different densities.The shift in density disrupts up the soundwave, which is why vibration isolation pads are made out of alternating levels of rubber, cork, and rubber. Dense, light, dense.

This helps us out a lot, since the transition from air to water loses a lot of sound as well. If our ears weren't such biological marvels that they had amplification devices built in specifically for water, we'd hear almost nothing as soon as our ears went below surface level. As it is, as long as people have their ears submerged (only really an issue if people are using neck pillows) that still does a lot of the heavy soundproofing for us.

And nothing is as large a transition as between air and solid.

So, one of the main goals of soundproofing becomes creating barriers with gaps of air between them. 'Heavy material and air gaps' is a good thing to imprint in your mind.

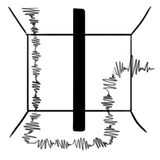

A room within a room is a direct extension of the 'air' + 'solid' idea. If you can surround one room completely with another room, you've done it! If you're speaking outside of this double room system, your voice (airborne) will hit the first wall (turning into vibrational noise), go into the air gap (going airborne again), hit the second wall (vibration), and finally go to the space on the inside (airborne) before someone standing inside will hear it.

That's a lot of transitions, and it's why this system is one of the core ideas of structural soundproofing. A float tank placed inside a 'Room within a Room' setup is pretty much a 'Room Within a Room Within a Room'... good news for soundproofing float tanks.

So how is the inside room supported? Where does the door go? What happens when you punch holes in your walls for plumbing and electrical? What about the fact that walls aren't 'solid,' they're a collection of drywall sheets hung closely together and covered in mud?

That, my floaty friends, is where the art comes in. Keep reading.

A room within a room is a direct extension of the 'air' + 'solid' idea. If you can surround one room completely with another room, you've done it! If you're speaking outside of this double room system, your voice (airborne) will hit the first wall (turning into vibrational noise), go into the air gap (going airborne again), hit the second wall (vibration), and finally go to the space on the inside (airborne) before someone standing inside will hear it.

That's a lot of transitions, and it's why this system is one of the core ideas of structural soundproofing. A float tank placed inside a 'Room within a Room' setup is pretty much a 'Room Within a Room Within a Room'... good news for soundproofing float tanks.

So how is the inside room supported? Where does the door go? What happens when you punch holes in your walls for plumbing and electrical? What about the fact that walls aren't 'solid,' they're a collection of drywall sheets hung closely together and covered in mud?

That, my floaty friends, is where the art comes in. Keep reading.

From there the airborne noise from the heels hits our walls (vibrational), goes into the rooms (airborne), then into the tank (vibrational), and finally into the tank air (airborne) and water (vibrational).

The clicking of the heels into tile (vibrational), goes into the concrete (vibrational), into the tank (vibrational), and into the water (vibrational).

Just looking at the difference between those two, we can see that although the number of transitions is similar, the vibrational noise through the floors never has to become airborne: the system is short-circuited.

We weren't hearing the clacking in the room while we were cleaning or even when we were just standing there listening for us, which provided good support for the idea that vibrational noise was the real issue.

[note: because things are so quiet while you're floating, simply not being able to hear something while you are standing in a room is not conclusive that it isn't an airborne issue. In this case though, it was good backup evidence.]

Fixing the problem meant fixing the short circuit, which meant decoupling some part of the system. Doing work in your neighbors space is annoying, and soundproofing their whole floor sounded intimidating, so that was a worst case scenario.

People sometime cut a line in the concrete to decouple areas of the foundation, but this is both expensive and in our case unfeasible: we consulting a couple experts who informed us that our foundation is to thin, and that the area we wanted to cut was too small, to be stable. So that was out.

From there the airborne noise from the heels hits our walls (vibrational), goes into the rooms (airborne), then into the tank (vibrational), and finally into the tank air (airborne) and water (vibrational).

The clicking of the heels into tile (vibrational), goes into the concrete (vibrational), into the tank (vibrational), and into the water (vibrational).

Just looking at the difference between those two, we can see that although the number of transitions is similar, the vibrational noise through the floors never has to become airborne: the system is short-circuited.

We weren't hearing the clacking in the room while we were cleaning or even when we were just standing there listening for us, which provided good support for the idea that vibrational noise was the real issue.

[note: because things are so quiet while you're floating, simply not being able to hear something while you are standing in a room is not conclusive that it isn't an airborne issue. In this case though, it was good backup evidence.]

Fixing the problem meant fixing the short circuit, which meant decoupling some part of the system. Doing work in your neighbors space is annoying, and soundproofing their whole floor sounded intimidating, so that was a worst case scenario.

People sometime cut a line in the concrete to decouple areas of the foundation, but this is both expensive and in our case unfeasible: we consulting a couple experts who informed us that our foundation is to thin, and that the area we wanted to cut was too small, to be stable. So that was out.

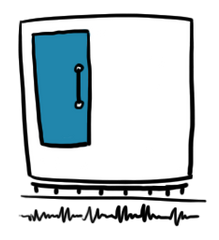

The easiest solution was to decouple our float tanks from the floor. How do we decouple a solid object (the tank) from a solid object (the floor) when we can't make it magically float (and thus actually eliminate contact)? For this we turn to sound isolators or, as they're more generically called, vibration isolation pads. Instead of sitting on the floor, your tank instead sits on a hard sheet (for example, plywood), which in turn rests on 11-15 vibration isolation pads (only 3" x 3") placed evenly underneath.

This reduces the surface area from 4500 square inches to 100 square inches. As mentioned before, the pads also alternate between light and dense materials, which further dampens the amount of vibrational noise transferred through each successive layer. Although this doesn't put a pure air gap in, it puts in a lot more air, and the few points that are connected break up the soundwave by switching density of material several times.

A nice side benefit is that this decoupling blocked a lot more than heels. That air/water transition we talked about before tackles a large amount of the airborne sound already, and our walls did a good job at getting the rest. So vibration really was our weakpoint, and after installing the sound isolator under our tanks, we heard less from cars, less from our own lobby, and just less in general.

The Shoe Machine Next Door

First we had to figure out what machine was making the noise. George, our neighbor, was kind enough to let us run some experiments. So, we threw on the owners in a tank, had him use his various machines, and had a runner go back and forth between his shop and ours until we found the culprit.

It was definitely not the machine we thought it was, nor was it an obvious candidate. And it was persistent - even after putting in the vibration isolation pads, the dull thud was still getting through.

So we made a small stand, put pads on the bottom of it, and put it under George's machine. This decoupled the machine from the floor on his side, so now there were two points of decoupling in the system. The machine was small and mobile enough that this was a possibility (whereas soundproofing the salon floor would have been a nightmare).

Voila! Shoe machine silenced!

How is the Inside Room Supported?

Or: if the Room Within a Room is supposed to have an air gap around it, how does it stay afloat? As we saw with the float tank, the best we can do is decouple it. Sometimes this means putting the tank on vibration isolation pads. Another more expensive solution is a full false floor.

For the ceiling, you can hang a drop ceiling, decoupled with special hangers that are mounted to your existing ceiling.

The easiest solution was to decouple our float tanks from the floor. How do we decouple a solid object (the tank) from a solid object (the floor) when we can't make it magically float (and thus actually eliminate contact)? For this we turn to sound isolators or, as they're more generically called, vibration isolation pads. Instead of sitting on the floor, your tank instead sits on a hard sheet (for example, plywood), which in turn rests on 11-15 vibration isolation pads (only 3" x 3") placed evenly underneath.

This reduces the surface area from 4500 square inches to 100 square inches. As mentioned before, the pads also alternate between light and dense materials, which further dampens the amount of vibrational noise transferred through each successive layer. Although this doesn't put a pure air gap in, it puts in a lot more air, and the few points that are connected break up the soundwave by switching density of material several times.

A nice side benefit is that this decoupling blocked a lot more than heels. That air/water transition we talked about before tackles a large amount of the airborne sound already, and our walls did a good job at getting the rest. So vibration really was our weakpoint, and after installing the sound isolator under our tanks, we heard less from cars, less from our own lobby, and just less in general.

The Shoe Machine Next Door

First we had to figure out what machine was making the noise. George, our neighbor, was kind enough to let us run some experiments. So, we threw on the owners in a tank, had him use his various machines, and had a runner go back and forth between his shop and ours until we found the culprit.

It was definitely not the machine we thought it was, nor was it an obvious candidate. And it was persistent - even after putting in the vibration isolation pads, the dull thud was still getting through.

So we made a small stand, put pads on the bottom of it, and put it under George's machine. This decoupled the machine from the floor on his side, so now there were two points of decoupling in the system. The machine was small and mobile enough that this was a possibility (whereas soundproofing the salon floor would have been a nightmare).

Voila! Shoe machine silenced!

How is the Inside Room Supported?

Or: if the Room Within a Room is supposed to have an air gap around it, how does it stay afloat? As we saw with the float tank, the best we can do is decouple it. Sometimes this means putting the tank on vibration isolation pads. Another more expensive solution is a full false floor.

For the ceiling, you can hang a drop ceiling, decoupled with special hangers that are mounted to your existing ceiling. For the walls, you can use single stud walls with sound channeling (to create an artificial gap), staggered stud walls (for an air gap, but which shares the same top and base plates), or totally separate double studs.

[IMPORTANT: Make sure the drywall on the outer wall goes all the way up to the roof. If it stops at the ceiling, that will be a large weak point in the system. We made this mistake, and had to cut open our ceiling and meticulously patch the joist bays to correct it.]

It's not a complete airgap, but it gets close.

Holes in your Walls for Plumbing and Electrical?

There are special fixtures specifically for soundproofing. For the electrical boxes, at the very least you end up wrapping them in sound putty (which is like a flexible clay you wrap around them before you put them in the wall). Sound caulk every seam, and before you seal your fixtures in, fill any gaps with sound caulk as well.

Another pro-tip is to be absolutely precise with your cuts in your walls - we measure 8 times and cut 4.

Your Walls Aren't One Solid Piece?

Sheetrock, or drywall, is usually hung in 4' x 8' sheets (we use extra thick, specifically soundproof sheetrock - QuietRock is an example - to add mass to the walls. It also has Green Glue between its layers for dampening). Because they are hung in several pieces, there are seams between them.

Each piece needs to be soundcaulked before it is placed (which, believe me, is very time consuming and wears out your hands - even if you have a superhuman grip) which fills in the cracks and makes it more of a seamless, soundproof system. It also dampens the vibration between sheets.

For the walls, you can use single stud walls with sound channeling (to create an artificial gap), staggered stud walls (for an air gap, but which shares the same top and base plates), or totally separate double studs.

[IMPORTANT: Make sure the drywall on the outer wall goes all the way up to the roof. If it stops at the ceiling, that will be a large weak point in the system. We made this mistake, and had to cut open our ceiling and meticulously patch the joist bays to correct it.]

It's not a complete airgap, but it gets close.

Holes in your Walls for Plumbing and Electrical?

There are special fixtures specifically for soundproofing. For the electrical boxes, at the very least you end up wrapping them in sound putty (which is like a flexible clay you wrap around them before you put them in the wall). Sound caulk every seam, and before you seal your fixtures in, fill any gaps with sound caulk as well.

Another pro-tip is to be absolutely precise with your cuts in your walls - we measure 8 times and cut 4.

Your Walls Aren't One Solid Piece?

Sheetrock, or drywall, is usually hung in 4' x 8' sheets (we use extra thick, specifically soundproof sheetrock - QuietRock is an example - to add mass to the walls. It also has Green Glue between its layers for dampening). Because they are hung in several pieces, there are seams between them.

Each piece needs to be soundcaulked before it is placed (which, believe me, is very time consuming and wears out your hands - even if you have a superhuman grip) which fills in the cracks and makes it more of a seamless, soundproof system. It also dampens the vibration between sheets.

Also, don't forget that everything you put up, in addition to being sound resistant, needs to be waterproof as well. I can say first hand that it's very painful to meticulously craft expensive, nearly silent rooms, only to have it rot out because you didn't know what type of grout to apply, what kind of paint to use, or what type of shower to install.

And even though hanging art is wonderful, don't hang it from your soundproof walls. You just spent a lot of time making a solid, impenetrable surface to block noise, and now you want to put a hole in it? Avoid putting holes of any kind in your walls, even if it's just a nail hole. And if you do, soundcaulk it in afterwards.

And finally, take what you can from all of this, and leave the rest. This blog post is equal parts anecdote and evidence, and if you feel confident launching into your own soundproofing based off of what is contained here, you should hop into a float tank and reconsider how you transmit information to action. Use this as a launching ground, but if you want to do your own work, you'll learn a tremendous amount, but you've got a long and often frustrating road ahead of you.

Also, don't forget that everything you put up, in addition to being sound resistant, needs to be waterproof as well. I can say first hand that it's very painful to meticulously craft expensive, nearly silent rooms, only to have it rot out because you didn't know what type of grout to apply, what kind of paint to use, or what type of shower to install.

And even though hanging art is wonderful, don't hang it from your soundproof walls. You just spent a lot of time making a solid, impenetrable surface to block noise, and now you want to put a hole in it? Avoid putting holes of any kind in your walls, even if it's just a nail hole. And if you do, soundcaulk it in afterwards.

And finally, take what you can from all of this, and leave the rest. This blog post is equal parts anecdote and evidence, and if you feel confident launching into your own soundproofing based off of what is contained here, you should hop into a float tank and reconsider how you transmit information to action. Use this as a launching ground, but if you want to do your own work, you'll learn a tremendous amount, but you've got a long and often frustrating road ahead of you.

We figured out a way to fix it, which we'll talk about below.

Then there was the rhythmic thudding, which we again found to be our neighbor, the shoe repairman (considering why we opened a sensory deprivation center next to a shoe repair shop should give you a good idea of our inexperience and unbridled optimism at this point). We thought it was one of his huge machines, but it ended up being one of his tiniest: it wasn't even loud in the shop, only in the tanks.

We fixed this as well.

Then there are the one offs, like the woman who got out because she thought she heard music when in fact it was just a sudden and very intense burst of hail against the ceiling vent. Or the time someone heard thudding which ended up being someone on our roof trying to burglarize our cannabis club neighbors (unsuccessfully). And at least three floaters a week describe sounds that only existed in their heads.

For everything we have fixed, there are twice as many mysteries that will probably never be solved.

We figured out a way to fix it, which we'll talk about below.

Then there was the rhythmic thudding, which we again found to be our neighbor, the shoe repairman (considering why we opened a sensory deprivation center next to a shoe repair shop should give you a good idea of our inexperience and unbridled optimism at this point). We thought it was one of his huge machines, but it ended up being one of his tiniest: it wasn't even loud in the shop, only in the tanks.

We fixed this as well.

Then there are the one offs, like the woman who got out because she thought she heard music when in fact it was just a sudden and very intense burst of hail against the ceiling vent. Or the time someone heard thudding which ended up being someone on our roof trying to burglarize our cannabis club neighbors (unsuccessfully). And at least three floaters a week describe sounds that only existed in their heads.

For everything we have fixed, there are twice as many mysteries that will probably never be solved.

Further Introductions

This is not a full-blown breakdown of soundproofing for a float center, but it is a good place to get the basics, learn some things to watch out for, and pick up a few acute solutions to common problems. Soundproofing is a complicated subject, and although we'll be getting our hands dirty with a lot of the theory, applying it affordably to our float tank rooms is very much a work in progress. A lot of the information here comes from study, a lot comes from consulting with float centers and manufacturers around the world, and an unfortunate amount comes from expensive mistakes that we've made in our own float center. Take everything you read here with a grain of salt, both for the obvious merits of float tank wordplay, and for the fact that a lot of this will probably change and progress along with the industry. If there's anything you've found works for you, definitely take a few moments to tell us about it in the comments - we're all in this together, and people will be able to immediately use your suggestions.

It is helpful to think of soundproofing for a float center as broken down into a few categories:

Take everything you read here with a grain of salt, both for the obvious merits of float tank wordplay, and for the fact that a lot of this will probably change and progress along with the industry. If there's anything you've found works for you, definitely take a few moments to tell us about it in the comments - we're all in this together, and people will be able to immediately use your suggestions.

It is helpful to think of soundproofing for a float center as broken down into a few categories:

- Surroundings location, neighbors, etc

- Your Building windows, walls, doors, foundation, layout, etc.

- Your Float Rooms soundproof/waterproof materials, electrical boxes, rooms within rooms, etc

- Your Float Tanks Water, earplugs, vibration isolation pads, air gaps, double vs single shell, etc.

The Mechanics of Noise

When we hear something, it's because the air particles around us are vibrating in a certain way. It's easy to forget, but sound is vibration, and our human bodies are only able to detect certain ranges of vibration (just as we can only see a very specific spectrum of light with our eyes).

Because our ears are underwater, and vibration travels so distinctly through water, this is an especially important concept to grasp for float tank owners.

Unsurprisingly, a lot of animals can detect sound vibration (which, by the way, is measured in Hertz, after Heinrich Rudolf Hertz, who proved the existence of electromagnetic waves) which humans cannot. How do we know that dolphins can hear up to 130,000 Hz while humans can only hear up to 20,000 Hz? The same reason we have float tanks: John Lilly.

Of other interest is that different noises produce different ranges of sound, and different types of soundproofing guard against different ranges of sound. Want to block out human voices? How about the bass from your neighbors stereo? Soundproofing materials often come with charts and profiles of the kinds of noises they block.

Sound intensity is measured in decibals (dB) which progresses in intensity exponentially. You may know it mainly as an audio term, but it's actually used as a common scale for many things in physics.

Basically all of our soundproofing is to reduce the volume of sound (dB) within the human hearing range (20-20,000hZ).

When we hear something, it's because the air particles around us are vibrating in a certain way. It's easy to forget, but sound is vibration, and our human bodies are only able to detect certain ranges of vibration (just as we can only see a very specific spectrum of light with our eyes).

Because our ears are underwater, and vibration travels so distinctly through water, this is an especially important concept to grasp for float tank owners.

Unsurprisingly, a lot of animals can detect sound vibration (which, by the way, is measured in Hertz, after Heinrich Rudolf Hertz, who proved the existence of electromagnetic waves) which humans cannot. How do we know that dolphins can hear up to 130,000 Hz while humans can only hear up to 20,000 Hz? The same reason we have float tanks: John Lilly.

Of other interest is that different noises produce different ranges of sound, and different types of soundproofing guard against different ranges of sound. Want to block out human voices? How about the bass from your neighbors stereo? Soundproofing materials often come with charts and profiles of the kinds of noises they block.

Sound intensity is measured in decibals (dB) which progresses in intensity exponentially. You may know it mainly as an audio term, but it's actually used as a common scale for many things in physics.

Basically all of our soundproofing is to reduce the volume of sound (dB) within the human hearing range (20-20,000hZ).

Airborne vs Vibrational Noise

When an airborne soundwave hits a solid object, it turns into vibrational noise. You can feel this internally when you're around a loud bass speaker. When an object is vibrating, it creates noise, which is turned back into airborne sound as it's vibration influences the air around it. Think of a bow being drawn across a violin. Or the vibrating speaker that produces the bass wave, which then hits your chest and begins vibrating again. This transition from air to solid to air to solid is important, because soundwaves lose strength as they travel through different densities.The shift in density disrupts up the soundwave, which is why vibration isolation pads are made out of alternating levels of rubber, cork, and rubber. Dense, light, dense.

This helps us out a lot, since the transition from air to water loses a lot of sound as well. If our ears weren't such biological marvels that they had amplification devices built in specifically for water, we'd hear almost nothing as soon as our ears went below surface level. As it is, as long as people have their ears submerged (only really an issue if people are using neck pillows) that still does a lot of the heavy soundproofing for us.

And nothing is as large a transition as between air and solid.

So, one of the main goals of soundproofing becomes creating barriers with gaps of air between them. 'Heavy material and air gaps' is a good thing to imprint in your mind.

This transition from air to solid to air to solid is important, because soundwaves lose strength as they travel through different densities.The shift in density disrupts up the soundwave, which is why vibration isolation pads are made out of alternating levels of rubber, cork, and rubber. Dense, light, dense.

This helps us out a lot, since the transition from air to water loses a lot of sound as well. If our ears weren't such biological marvels that they had amplification devices built in specifically for water, we'd hear almost nothing as soon as our ears went below surface level. As it is, as long as people have their ears submerged (only really an issue if people are using neck pillows) that still does a lot of the heavy soundproofing for us.

And nothing is as large a transition as between air and solid.

So, one of the main goals of soundproofing becomes creating barriers with gaps of air between them. 'Heavy material and air gaps' is a good thing to imprint in your mind.

Room Within a Room

A room within a room is a direct extension of the 'air' + 'solid' idea. If you can surround one room completely with another room, you've done it! If you're speaking outside of this double room system, your voice (airborne) will hit the first wall (turning into vibrational noise), go into the air gap (going airborne again), hit the second wall (vibration), and finally go to the space on the inside (airborne) before someone standing inside will hear it.

That's a lot of transitions, and it's why this system is one of the core ideas of structural soundproofing. A float tank placed inside a 'Room within a Room' setup is pretty much a 'Room Within a Room Within a Room'... good news for soundproofing float tanks.

So how is the inside room supported? Where does the door go? What happens when you punch holes in your walls for plumbing and electrical? What about the fact that walls aren't 'solid,' they're a collection of drywall sheets hung closely together and covered in mud?

That, my floaty friends, is where the art comes in. Keep reading.

A room within a room is a direct extension of the 'air' + 'solid' idea. If you can surround one room completely with another room, you've done it! If you're speaking outside of this double room system, your voice (airborne) will hit the first wall (turning into vibrational noise), go into the air gap (going airborne again), hit the second wall (vibration), and finally go to the space on the inside (airborne) before someone standing inside will hear it.

That's a lot of transitions, and it's why this system is one of the core ideas of structural soundproofing. A float tank placed inside a 'Room within a Room' setup is pretty much a 'Room Within a Room Within a Room'... good news for soundproofing float tanks.

So how is the inside room supported? Where does the door go? What happens when you punch holes in your walls for plumbing and electrical? What about the fact that walls aren't 'solid,' they're a collection of drywall sheets hung closely together and covered in mud?

That, my floaty friends, is where the art comes in. Keep reading.

Decoupling, Adding Mass, Absorption, and Damping

That air gap between the two rooms in our example? That's an example of decoupling. Where you don't have a solid piece going through, the sound can't vibrate around it. As soon as you have a solid piece connecting two parts through the air gap you've 'short-circuited' the system. A system loses a lot of its quality if even a single solid piece is touching between separate elements. The walls? That's where adding mass comes in. The heavier and thicker those walls are, the more they'll block the sound coming through. As with the decoupling though, its important for the mass to be solid. Sound waves are sneaky, and if there's a way, they'll find their way around the heaviest of walls without even having to go through. (hint: the floor and ceilings are two huge culprits that we didn't even think about at the beginning). Absorption is what makes sure that your air gaps don't resonate. You know the ocean sound when you put a shell up to your ear? That's the sound of air inside a cavity, and you can bet that that's what's going on inside your walls as well, along with the echo of the vibrations bouncing off the inner and outer walls. Insulation inside the wall cavity is the typical way to combat this. Damping is what you do to make it so that the solids that are vibrating with the sound wave don't vibrate as much. If you could stop them from vibrating at all, you'd effectively stop the sound waves from ever passing them. Green Glue, put between two sheets of drywall, is a typical method for this in construction. The Green Glue prevents the sound wave from getting through to the second layer as much, preventing some of the vibration. With those concepts under your belt, and armed with the idea of rooms in rooms in room ad infinitum, we're ready for some float specific construction!A Few Float Tank Solutions

Now that we've learned some soundproofing basics, let's revisit some of the problems brought up earlier in the post. The Clacking of the Heels The heels were hitting tile, then going two place: airborne noise (into our walls) and vibrational noise (into the concrete foundation that connected their shop to ours). From there the airborne noise from the heels hits our walls (vibrational), goes into the rooms (airborne), then into the tank (vibrational), and finally into the tank air (airborne) and water (vibrational).

The clicking of the heels into tile (vibrational), goes into the concrete (vibrational), into the tank (vibrational), and into the water (vibrational).

Just looking at the difference between those two, we can see that although the number of transitions is similar, the vibrational noise through the floors never has to become airborne: the system is short-circuited.

We weren't hearing the clacking in the room while we were cleaning or even when we were just standing there listening for us, which provided good support for the idea that vibrational noise was the real issue.

[note: because things are so quiet while you're floating, simply not being able to hear something while you are standing in a room is not conclusive that it isn't an airborne issue. In this case though, it was good backup evidence.]

Fixing the problem meant fixing the short circuit, which meant decoupling some part of the system. Doing work in your neighbors space is annoying, and soundproofing their whole floor sounded intimidating, so that was a worst case scenario.

People sometime cut a line in the concrete to decouple areas of the foundation, but this is both expensive and in our case unfeasible: we consulting a couple experts who informed us that our foundation is to thin, and that the area we wanted to cut was too small, to be stable. So that was out.

From there the airborne noise from the heels hits our walls (vibrational), goes into the rooms (airborne), then into the tank (vibrational), and finally into the tank air (airborne) and water (vibrational).

The clicking of the heels into tile (vibrational), goes into the concrete (vibrational), into the tank (vibrational), and into the water (vibrational).

Just looking at the difference between those two, we can see that although the number of transitions is similar, the vibrational noise through the floors never has to become airborne: the system is short-circuited.

We weren't hearing the clacking in the room while we were cleaning or even when we were just standing there listening for us, which provided good support for the idea that vibrational noise was the real issue.

[note: because things are so quiet while you're floating, simply not being able to hear something while you are standing in a room is not conclusive that it isn't an airborne issue. In this case though, it was good backup evidence.]

Fixing the problem meant fixing the short circuit, which meant decoupling some part of the system. Doing work in your neighbors space is annoying, and soundproofing their whole floor sounded intimidating, so that was a worst case scenario.

People sometime cut a line in the concrete to decouple areas of the foundation, but this is both expensive and in our case unfeasible: we consulting a couple experts who informed us that our foundation is to thin, and that the area we wanted to cut was too small, to be stable. So that was out.

The easiest solution was to decouple our float tanks from the floor. How do we decouple a solid object (the tank) from a solid object (the floor) when we can't make it magically float (and thus actually eliminate contact)? For this we turn to sound isolators or, as they're more generically called, vibration isolation pads. Instead of sitting on the floor, your tank instead sits on a hard sheet (for example, plywood), which in turn rests on 11-15 vibration isolation pads (only 3" x 3") placed evenly underneath.

This reduces the surface area from 4500 square inches to 100 square inches. As mentioned before, the pads also alternate between light and dense materials, which further dampens the amount of vibrational noise transferred through each successive layer. Although this doesn't put a pure air gap in, it puts in a lot more air, and the few points that are connected break up the soundwave by switching density of material several times.

A nice side benefit is that this decoupling blocked a lot more than heels. That air/water transition we talked about before tackles a large amount of the airborne sound already, and our walls did a good job at getting the rest. So vibration really was our weakpoint, and after installing the sound isolator under our tanks, we heard less from cars, less from our own lobby, and just less in general.

The Shoe Machine Next Door

First we had to figure out what machine was making the noise. George, our neighbor, was kind enough to let us run some experiments. So, we threw on the owners in a tank, had him use his various machines, and had a runner go back and forth between his shop and ours until we found the culprit.

It was definitely not the machine we thought it was, nor was it an obvious candidate. And it was persistent - even after putting in the vibration isolation pads, the dull thud was still getting through.

So we made a small stand, put pads on the bottom of it, and put it under George's machine. This decoupled the machine from the floor on his side, so now there were two points of decoupling in the system. The machine was small and mobile enough that this was a possibility (whereas soundproofing the salon floor would have been a nightmare).

Voila! Shoe machine silenced!

How is the Inside Room Supported?

Or: if the Room Within a Room is supposed to have an air gap around it, how does it stay afloat? As we saw with the float tank, the best we can do is decouple it. Sometimes this means putting the tank on vibration isolation pads. Another more expensive solution is a full false floor.

For the ceiling, you can hang a drop ceiling, decoupled with special hangers that are mounted to your existing ceiling.

The easiest solution was to decouple our float tanks from the floor. How do we decouple a solid object (the tank) from a solid object (the floor) when we can't make it magically float (and thus actually eliminate contact)? For this we turn to sound isolators or, as they're more generically called, vibration isolation pads. Instead of sitting on the floor, your tank instead sits on a hard sheet (for example, plywood), which in turn rests on 11-15 vibration isolation pads (only 3" x 3") placed evenly underneath.

This reduces the surface area from 4500 square inches to 100 square inches. As mentioned before, the pads also alternate between light and dense materials, which further dampens the amount of vibrational noise transferred through each successive layer. Although this doesn't put a pure air gap in, it puts in a lot more air, and the few points that are connected break up the soundwave by switching density of material several times.

A nice side benefit is that this decoupling blocked a lot more than heels. That air/water transition we talked about before tackles a large amount of the airborne sound already, and our walls did a good job at getting the rest. So vibration really was our weakpoint, and after installing the sound isolator under our tanks, we heard less from cars, less from our own lobby, and just less in general.

The Shoe Machine Next Door

First we had to figure out what machine was making the noise. George, our neighbor, was kind enough to let us run some experiments. So, we threw on the owners in a tank, had him use his various machines, and had a runner go back and forth between his shop and ours until we found the culprit.

It was definitely not the machine we thought it was, nor was it an obvious candidate. And it was persistent - even after putting in the vibration isolation pads, the dull thud was still getting through.

So we made a small stand, put pads on the bottom of it, and put it under George's machine. This decoupled the machine from the floor on his side, so now there were two points of decoupling in the system. The machine was small and mobile enough that this was a possibility (whereas soundproofing the salon floor would have been a nightmare).

Voila! Shoe machine silenced!

How is the Inside Room Supported?

Or: if the Room Within a Room is supposed to have an air gap around it, how does it stay afloat? As we saw with the float tank, the best we can do is decouple it. Sometimes this means putting the tank on vibration isolation pads. Another more expensive solution is a full false floor.

For the ceiling, you can hang a drop ceiling, decoupled with special hangers that are mounted to your existing ceiling. For the walls, you can use single stud walls with sound channeling (to create an artificial gap), staggered stud walls (for an air gap, but which shares the same top and base plates), or totally separate double studs.

[IMPORTANT: Make sure the drywall on the outer wall goes all the way up to the roof. If it stops at the ceiling, that will be a large weak point in the system. We made this mistake, and had to cut open our ceiling and meticulously patch the joist bays to correct it.]

It's not a complete airgap, but it gets close.

Holes in your Walls for Plumbing and Electrical?

There are special fixtures specifically for soundproofing. For the electrical boxes, at the very least you end up wrapping them in sound putty (which is like a flexible clay you wrap around them before you put them in the wall). Sound caulk every seam, and before you seal your fixtures in, fill any gaps with sound caulk as well.

Another pro-tip is to be absolutely precise with your cuts in your walls - we measure 8 times and cut 4.

Your Walls Aren't One Solid Piece?

Sheetrock, or drywall, is usually hung in 4' x 8' sheets (we use extra thick, specifically soundproof sheetrock - QuietRock is an example - to add mass to the walls. It also has Green Glue between its layers for dampening). Because they are hung in several pieces, there are seams between them.

Each piece needs to be soundcaulked before it is placed (which, believe me, is very time consuming and wears out your hands - even if you have a superhuman grip) which fills in the cracks and makes it more of a seamless, soundproof system. It also dampens the vibration between sheets.

For the walls, you can use single stud walls with sound channeling (to create an artificial gap), staggered stud walls (for an air gap, but which shares the same top and base plates), or totally separate double studs.

[IMPORTANT: Make sure the drywall on the outer wall goes all the way up to the roof. If it stops at the ceiling, that will be a large weak point in the system. We made this mistake, and had to cut open our ceiling and meticulously patch the joist bays to correct it.]

It's not a complete airgap, but it gets close.

Holes in your Walls for Plumbing and Electrical?

There are special fixtures specifically for soundproofing. For the electrical boxes, at the very least you end up wrapping them in sound putty (which is like a flexible clay you wrap around them before you put them in the wall). Sound caulk every seam, and before you seal your fixtures in, fill any gaps with sound caulk as well.

Another pro-tip is to be absolutely precise with your cuts in your walls - we measure 8 times and cut 4.

Your Walls Aren't One Solid Piece?

Sheetrock, or drywall, is usually hung in 4' x 8' sheets (we use extra thick, specifically soundproof sheetrock - QuietRock is an example - to add mass to the walls. It also has Green Glue between its layers for dampening). Because they are hung in several pieces, there are seams between them.

Each piece needs to be soundcaulked before it is placed (which, believe me, is very time consuming and wears out your hands - even if you have a superhuman grip) which fills in the cracks and makes it more of a seamless, soundproof system. It also dampens the vibration between sheets.

Closing Words

This post is meant as an introduction to some important soundproofing concepts, but it's always a good idea to consult a professional before you actually begin construction. These materials are many times more expensive than typical, which makes mistakes many times more expensive. Also, don't forget that everything you put up, in addition to being sound resistant, needs to be waterproof as well. I can say first hand that it's very painful to meticulously craft expensive, nearly silent rooms, only to have it rot out because you didn't know what type of grout to apply, what kind of paint to use, or what type of shower to install.

And even though hanging art is wonderful, don't hang it from your soundproof walls. You just spent a lot of time making a solid, impenetrable surface to block noise, and now you want to put a hole in it? Avoid putting holes of any kind in your walls, even if it's just a nail hole. And if you do, soundcaulk it in afterwards.

And finally, take what you can from all of this, and leave the rest. This blog post is equal parts anecdote and evidence, and if you feel confident launching into your own soundproofing based off of what is contained here, you should hop into a float tank and reconsider how you transmit information to action. Use this as a launching ground, but if you want to do your own work, you'll learn a tremendous amount, but you've got a long and often frustrating road ahead of you.

Also, don't forget that everything you put up, in addition to being sound resistant, needs to be waterproof as well. I can say first hand that it's very painful to meticulously craft expensive, nearly silent rooms, only to have it rot out because you didn't know what type of grout to apply, what kind of paint to use, or what type of shower to install.

And even though hanging art is wonderful, don't hang it from your soundproof walls. You just spent a lot of time making a solid, impenetrable surface to block noise, and now you want to put a hole in it? Avoid putting holes of any kind in your walls, even if it's just a nail hole. And if you do, soundcaulk it in afterwards.

And finally, take what you can from all of this, and leave the rest. This blog post is equal parts anecdote and evidence, and if you feel confident launching into your own soundproofing based off of what is contained here, you should hop into a float tank and reconsider how you transmit information to action. Use this as a launching ground, but if you want to do your own work, you'll learn a tremendous amount, but you've got a long and often frustrating road ahead of you.

Thanks Dylan, for letting me write this post and share it with your audience. It's been an absolute pleasure writing it, and I hope that I get a chance to do it again. And thank you for reading all of this, and for being this strange and salty community. Float on!

--

Graham Talley is a Co Founder of Float On (which runs over 1,000 floats a month out of Portland, OR) and of Float Tank Solutions (which provides resources for starting and running your float center). He spends most of his time consulting and slaving away at his own center, but he occasionally gets to divert himself with planning the Float Conference and, more recently, republishing the works of John Lilly (starting with Programming and Metaprogramming in the Human Biocomputer - being released May 15, 2014).